Aquaculture Air Systems

Specialist Air Solutions & Products for Aquaculture Applications

We are an experienced supplier of specialist air solutions to the Scottish Aquaculture community. Our quality products are designed and built for maximum durability while ensuring process reliability and efficiency.

Also known as fish farming, Aquaculture is effectively farming in water. It is an environmentally responsible source of food and commercial products that can help to create healthier habitats and rebuild stocks of threatened or endangered species.

Get a Free QuoteWhy is Air Important to Fish Farming & Aquaculture?

The Aquaculture industry specialises in the controlled process of cultivating and harvesting aquatic species. These species include fish, shellfish, and plants primarily produced for human consumption.

Operators of fish farms and Aquaculture sites, whether onshore or offshore, depend on a reliable, quality supply of low-pressure air and compressed air for a variety of equipment, systems and processes. Short downtime of critical equipment, such as a low-pressure blower or air compressor, causing an interruption to the air supply, can lead to major issues and potentially mass stock mortalities.

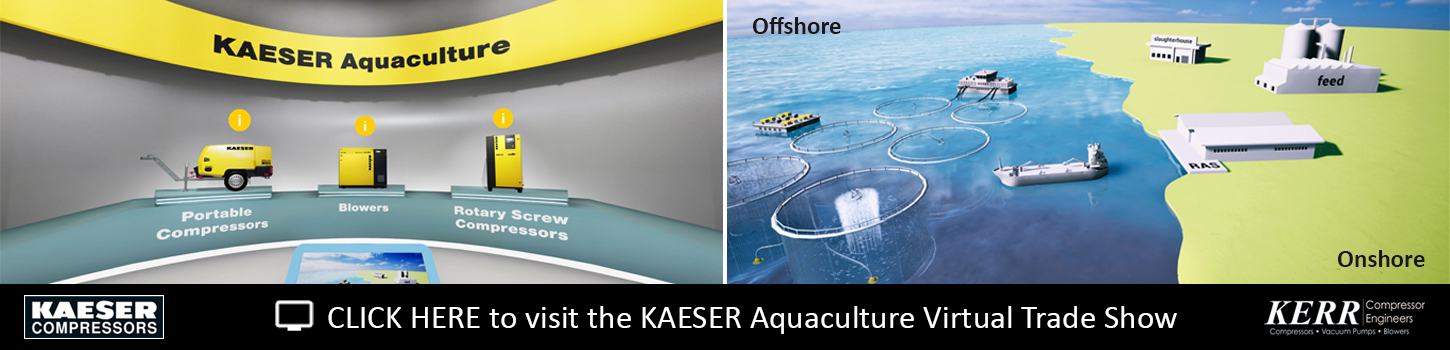

A range of reliable KAESER air products are specifically designed and built to provide maximum durability in Aquaculture environments and ensure maximum process reliability to minimise the risk of downtime. An established and experienced supplier to the Scottish Aquaculture community, we are the UK's number one Authorised Distributor for KAESER HPC.

Our systems' impressive energy efficiency helps keep the largest part of total system costs to a minimum, whilst the low maintenance requirement reduces costs even further.

How is Compressed Air used in Aquaculture?

Low-pressure air and compressed air are used in a variety of aquaculture applications. Examples include:

Bubble Curtains:

In recent years, fish farms have faced increasing problems and risks from jellyfish and algae blooms. A “bubble curtain” system is a simple yet effective method of preventing jellyfish and algae from adversely affecting fish within a sea pen.

When a threat is reported or identified, a compressor is activated to deliver air to an underwater delivery system that produces a ring of air bubbles around the pen. The rising bubbles and water turbulence effectively create a ‘curtain’, preventing algae or jellyfish from entering the fish pen. The natural marine current drives the threat alongside the bubble curtain until it passes safely beyond the farm.

Feed Barges:

Feed barges are essential for the efficient operation of modern offshore fish farms. Some are capable of carrying up to 850 tonnes of feed. As can be seen in our Aquaculture video (above) and as featured in our blog, innovative and efficient rotary blower technologies from KAESER generate the airflow required to deliver the feed into the farming pens.

Read our blog - 'Utilising Low Pressure Air & Compressed Air in Aquaculture'Feed barges may also be equipped with a rotary screw air compressor for Sea Pen Aeration (SPA) systems, bubble curtains or airlift systems to remove dead fish from the pens.

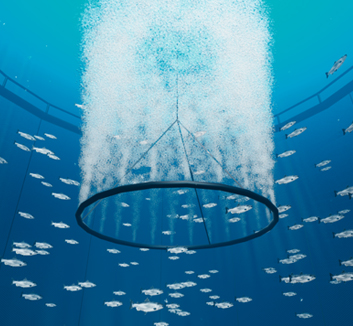

Sea Pen Aeration (SPA):

Two significant problems of sea pen farming are algae blooms and oxygen deficiency. Sea Pen Aeration (SPA) systems can solve both problems at the same time. A compressor blows air into a diffuser ring; this generates an upward flow within the pen that lifts cool, oxygen-rich water from the depths into the sea pen.

At the surface, the water then flows outwards, preventing algae and plankton (as well as planktonic stages of sea lice) from entering the sea pen. The rising bubbles also increase the oxygen saturation of the water, thus lowering the feed conversion ratio and improving the overall health of the fish.

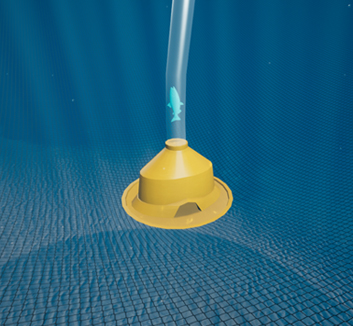

Airlift Systems:

Dead fish are vectors for diseases and infections, causing further mortality if not removed effectively and efficiently. The most reliable and efficient prevention is removing the morts via an airlift system. Here, a conical device supplied with compressed air is placed at the deepest point of an aquaculture pen.

A rotary screw compressor provides the air required to retrieve and transfer the remains and waste through tubing onto a support barge or boat. The contaminated water is then cleaned from waste and can then be discharged safely into deeper water afterwards.

Fish Processing:

Once fish stock is harvested, it must be processed quickly and efficiently. Accurate automated conveying, sorting, gutting and processing systems operated by low-pressure air and vacuum helps to reduce failure rates and results in a reduction of manpower on manual cleaning lines. Exhausters facilitate the efficient operation of suction lines for quick and effective gut / waste removal.

Read our Aquaculture case study - 'Bespoke Farmed Fish Vacuum Processing System'

KAESER Aquaculture Products Include:

Rotary Screw Compressors:

Rotary screw compressors deliver a reliable and efficient supply of quality compressed air. They are the preferred choice for users requiring constant pressure over prolonged periods. In Aquaculture applications, they are preferably used to supply PSA oxygen generators with compressed air, to form bubble curtains against algae or jellyfish incursion, or to create artificial upwelling to lift cool water from deeper layers up to the surface.

MOBILAIR Portable Compressors:

Compressed air whenever you need it, wherever you need it – even under the toughest offshore conditions: specially designed and modified powerful MOBILAIR Portable Compressors with advanced, fuel-efficient engines and heavy-duty construction are available in a wide range of models and configurations. Many models feature a roto-moulded PE enclosure to ensure extreme dent resistance for the harshest offshore conditions. Simple and intuitive operation and optimal maintenance point accessibility prevents unnecessary downtime.

Rotary Blowers & Exhausters:

Low-maintenance, highly reliable KAESER Rotary Blowers deliver pressurised air quietly and efficiently for multiple marine applications. These include the pneumatic conveying of bulk loads, for onboard wastewater treatment, bubble curtains and in anti-heeling systems. Two different design concepts help to meet your specific requirements:

- Rotary lobe blowers feature efficient, three-lobe OMEGA blower blocks for minimal pulsation effects

- Alternatively, Rotary screw blowers feature the energy-saving SIGMA PROFILE – designed by KAESER for optimal pressure and output. High-efficiency Rotary screw blowers can save up to 30% energy compared to comparable roots blowers

Air Treatment & Storage:

Refrigerant Air Dryers and Compressed Air Filtration ensure dry, clean, quality compressed to ISO Standards by removing potentially harmful contaminants from the supply and combating the enemies of compressed air applications- water, oil and dust. Dryers, filters and specialist air treatment equipment provide effective, reliable protection against condensate damage or contaminants affecting your systems, processes and product quality. In addition, air receivers store and maintain large volumes of compressed air at pressure.

Have you read our Aquaculture blog? Click here to read - 'Specialised Aquaculture Applications Require Specialised Products & Solutions'