May 2021

May 2021

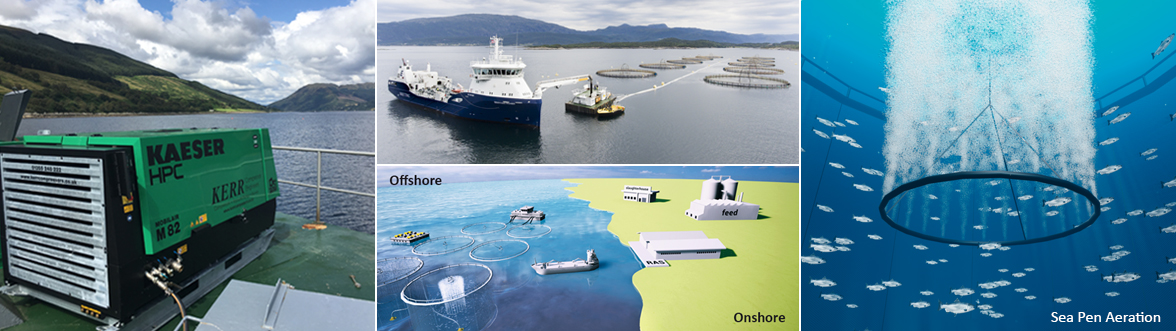

Specialised Aquaculture Applications Require Specialised Products & Solutions

Salmon Aquaculture and the use of sea pens to farm salmon is a booming segment of the food industry. Profit margins are ever high, as is consumer demand. This has led to the increasing use of technology by the Aquaculture industry, much of which relies on the use of compressed air and low-pressure air.

Salmon feeding has been a pneumatic procedure for over 12 years, whereby the feed is directed from the feed silo into the pens by a low-pressure air stream. This tried-and-tested technique is now leading to feed barges being designed with machine rooms beside the feed silos in which the blowers and any ancillary equipment can be housed to protect them from the outside elements.

Compressed Air Applications In Aquaculture

In recent years, higher-pressure compressed air applications have increasingly found their way into the Aquaculture industry. Operating in the 7-bar range, compressors – either diesel or electric powered – are used to provide the compressed air for important tasks such as removing dead fish from the pens (mort removal) or raising the level of oxygen in the sea pens (a procedure known as ‘Sea Pen Aeration - SPA’).

Airlift Systems

Prior to the innovative technique of automating mort removal, divers were dispatched to the pens to manually place the dead fish in baskets which then had to be lifted out of the water by hand. Now, using compressed air to do the job instead, a cone is installed in the deepest part of the sea pens.

This is connected to a tube through which compressed air is blown, forcing the dead fish up from the bottom of the pen to the top, owing to the “airlift pump” principle. Here they are separated from the water so that skilled staff can assess the condition of the carcasses and conduct statistical analyses on them.

This is far quicker and less labour-intensive than the previous manual process and removal of the carcasses sooner rather than later also helps prevent the spread of disease. A recent further development to the idea of extracting the carcasses in this way is to do the same with faecal matter. This concept is already being tested in closed pens on test farms and could be used in future in areas where both water quality and environmental impact are of key concern.

Sea Pen Aeration (SPA)

One of the most important uses for compressed air in Aquaculture is ‘Sea Pen Aeration - SPA’, a process whereby compressed air is blown into the pens through diffusers.

As bubbles rise to the surface, a gas exchange takes place between the water and the gases in the bubbles, raising the oxygen levels in the water. Even more importantly, it results in an artificial upwelling, which forces oxygen-rich, cold water from deeper down in the water column up into the pens.

This has several effects:

- Firstly, because colder, deep waters can hold more oxygen, the oxygen levels in the pens are raised. This is particularly important in the summer months when environmental factors such as algal blooms can be a major concern. Cold, deep waters also mitigate the effects of temperature peaks, which are dangerous for the salmon and have become increasingly common during the summer months in recent years.

- A further effect of the upwelling is that, thanks to the water at the upper levels flowing outwards, less of the oxygen-poor surface water enters the pens. Moreover, algae drifting in upper water layers is kept out of the sea pens by the outwards flow. This effect is most important during algae blooms and prevent the algae from reaching the Salmon.

Bubble Curtains

The SPA concept described above is currently most commonly used in Canada and Norway. In other countries, including Scotland and Chile, bubble curtains are the usual method for protecting the fish from swarms of jellyfish (Scotland) and algal blooms (Chile).

In the past, these two blights have been responsible for wiping out entire fish stocks in some farms and resulted in financial losses totalling millions.

Such compressor applications are relatively new, so most feed barges have nowhere to house the associated necessary equipment. This means that the compressors tend either to be installed at the farms themselves or on rafts specially designed and built to accommodate them.

Extreme Environment and Marine Application Requirements

Compressors with electric drive motors are usually housed within a container, whereas diesel-powered compressors are generally left exposed to the elements. However, both types of compressor were traditionally designed for use on land; the harsh conditions found at sea, with constant exposure to saltwater, were not part of the design brief.

This weak link in the design chain has led to premature problems occurring with compressor operation, particularly under the tough operating conditions associated with maritime use. However, compressors are essential to protect fish farms against such existential threats as jellyfish swarms, algal blooms or other potentially critical dangers in an emergency. For this reason, downtime due to the failure of the electrical system for example, is unacceptable and operational reliability is paramount.

Specialist Design & Protection

It was Thomas Kaeser himself, Chairman of the Board at KAESER Kompressoren SE, who recognised the special needs of the Aquaculture industry and therefore commissioned an Aquaculture specialist to examine the specific issues at hand. The company subsequently spent some time becoming intensely acquainted with the global Aquaculture sector. It looked at the issues that compressor equipment and air products face in this difficult operating environment, analysed the key Aquaculture markets and liaised closely with experienced fish farmers, specialist suppliers and plant hire companies from all around the world.

Equipped with this knowledge, KAESER was able to develop the first prototype of a compressor that was designed specifically for use in the Aquaculture industry. Introduced to the world at the AquaSur 2018 trade fair in Chile, this ground-breaking innovation was built to withstand maritime environments and to ensure maximum operational reliability.

Through continuous consultation with end customers, this prototype has been further refined so that KAESER can now offer a compressor configuration which delivers even greater reliability under the harsh conditions that go hand-in-hand with Aquaculture applications. This, in combination with increased compressor service life, means that plant hire companies, suppliers and fish farmers alike can enjoy the significant advantages that KAESER compressed air solutions for Aquaculture applications provide.

KAESER Kompressoren SE is a family-owned German company that recently celebrated its centenary year. KAESER air compressors and blowers are renowned throughout the world for their high quality, outstanding reliability and exceptional energy efficiency.

A range of reliable KAESER air products are specifically designed and built to provide maximum durability in Aquaculture environments and ensure maximum process reliability to minimise the risk of downtime. Kerr Compressor Engineers is the sole Scottish Authorised Distributor of KAESER HPC air products and an established and experienced supplier to the Scottish Aquaculture community.

For futher information and advice on specialised Aquaculture products and solutions, please contact our expert team on:

0800 008 6588 - web.enquiry@kerrcompressors.co.uk

Read more on our Aquaculture Applications & Solutions page

Recent Comments