Air Compressor Energy Audit

ANALYSIS & ADVICE | Air Compressor Energy Auditing

World-class compressed air consulting, expert air compressor energy audits and accurate data logging for trades, manufacturing & industry.

Whether regarding data logging, air demand analysis, optimisation of an existing compressed air system or tailored planning of a new system: Kerr Compressors customers all over Scotland and KAESER customers all around the world, benefit from the consulting and analysis expertise from experienced specialist engineers and one of the world's largest leading compressed air systems providers.

With specially developed analytical methods that comply with ISO 11011 and a trained instinct for the needs of the broadest range of industries, our engineers create future-proof solutions precisely tailored to meet your needs and which not only save money but are also kind to the environment.

Is it time your business had an air compressor energy audit?

Get a Free Quote

We work with you to discuss & design your compressed air future in four logical steps:

Step 1 – We discuss, listen & understand your individual needs

No two businesses or requirements are the same. This is why our specialist engineers first create a precise and detailed requirement profile for each of your fields of application. Your new compressed air system must be as individual as your requirements as an operator. Therefore, we explore, discuss, listen carefully and pay close attention to all the details by asking the right questions.

We are also helped by our experience and multi-industry knowledge – so whether you manufacture jewellery or semiconductors or operate a factory, an automotive body shop, an Aquaculture site or a distillery, Kerr Compressors is always familiar with your field of expertise and business.

Together, we work closely with you to gather all the necessary production parameters, conditions and potential future requirements.

These include:- Air quality: Do you require standard blowing air or clean room quality Class 0 air according to ISO 8573-1?

- Existing components: Which compressors and consumers are already installed? Is there a master controller? What is the condition of the pipe network? Is heat recovery used?

- Installation location: What is the condition of the supply air, air circulation and exhaust ducting? What are the space conditions like? What are the ambient conditions like? What is the condition or limitations of the electrical supply?

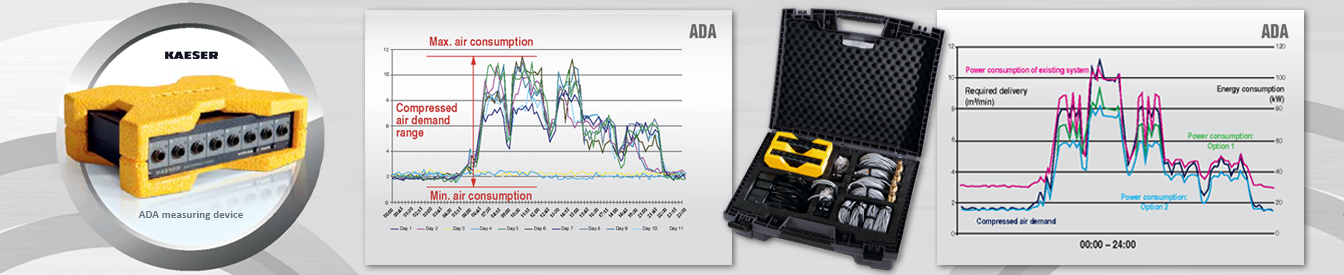

Step 2 – Air Demand Analysis (ADA) & Air Compressor Energy Audit

Using the latest innovative technology of our KAESER Air Demand Analysers (ADA-2 data-loggers), we generate precise computer-aided evaluations and consumption profiles of your compressed air system. Data logging allows us to accurately monitor, record and determine your actual air demand – throughout all operating sectors and at different loads. This includes:

- highlighting potential or current weaknesses in your existing system

- identifying poorly designed or dimensioned installations

- laying the groundwork for the next step toward the optimal compressed air system by calculating the energy-saving potential

- taking the widest range of conditions into account – regardless of whether you are looking to install a new system or wish to test the efficiency of your existing system

The Air Demand Analysis process in more detail:

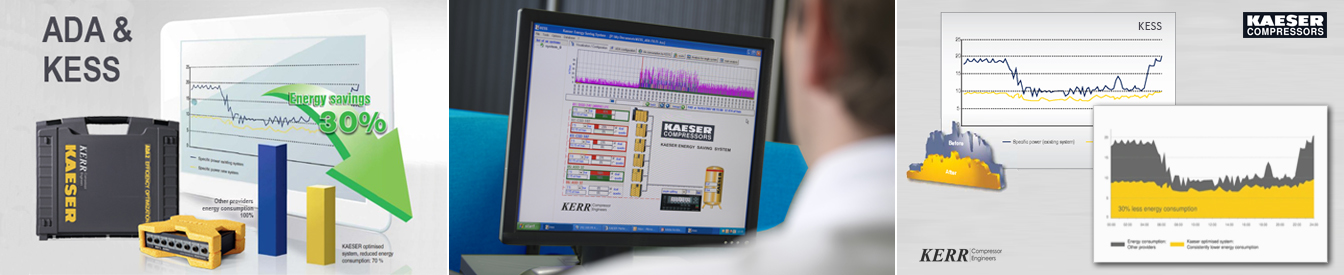

Step 3 – KAESER Energy-Saving System (KESS)

KAESER’s Air Demand Analysis (ADA) and the KAESER Energy Saving System (KESS) are advanced, proprietary tools that provide the basis for outstanding compressed air supply efficiency and dependability.

Energy savings calculation with KESS can reduce your costs by up to 30% - using KESS, we process the data determined by the ADA and design a compressed air supply system for you that saves up to 30% of your energy costs – possibly more. In addition:

- we then compare several possible concepts to achieve the best possible efficiency

- we consider the system's performance during its overall service life. This means that any weak points in partial load operation can be detected in advance and remedied

- we forecast the performance of your station and compare promising energy-saving models

Getting a Grip on your Energy Costs

Using ADA and KESS, our specialist engineers can plan and design a specifically tailored system to meet all of your compressed air requirements that will keep your compressed air operating costs to an absolute minimum.

The result: up to 30% lower energy costs, possibly more in some cases.

Step 4 – The optimum compressed air system solution

You have reached your objective: Your compressed air future starts now. Based on the ADA compressed air consumption profile and the KESS – KAESER Energy Saving System, our expert engineers recommend the most economical compressed air system configuration for your individual requirements and accompany this through planning to implementation.

You benefit from our experience, systematic planning and expert advice over the long term:

- Thanks to over 40 years of specialised industry and project experience, we have a detailed understanding of your particular field of business. You will receive a solution that meets your specific requirements and provides you with a wide range of options for the future

- From the outset of the planning stage, we develop a tailored continuity concept while taking into account maximum air supply security

- Following commissioning, our specialist engineers continue to work with and assist you to ensure a long and highly efficient service life through preventative maintenance and utilising genuine spare parts

Analysis & Advice

(ADA & KESS) Brochure

Analysis & Advice

(ADA & KESS) Brochure