Air Management Systems & Air Compressor Controllers

Compressed Air Management Systems & Controllers - Innovation meets Efficiency

Get a Free QuoteAir Controls and Compressors - Industry 4.0 interconnects man and machine, equipment and components utilising advanced digital information technology for effective compressed air management.

This technological revolution with air controls and compressors is also about real-time information exchange – about data that can be transferred and

analysed in real-time. It is this capability that provides users with a real competitive edge. It also opens up new value-added potential

by ensuring permanent utility and availability of important industrial equipment, for example.

Sigma Control 2 – Fitted as standard to all compressors.

Stay Connected – Optional on SX-ASK Models

SIGMA AIR MANAGER 4.0

KAESER's next generation compressed air management system & master controller with Adaptive 3D Control

SIGMA CONTROL 2 - SC2

The latest evolution of the KAESER compressor controller featuring further innovations in Energy EfficiencySIGMA AIR MANAGER 4.0

Industry 4.0 – Intelligent maintenance and efficiency management

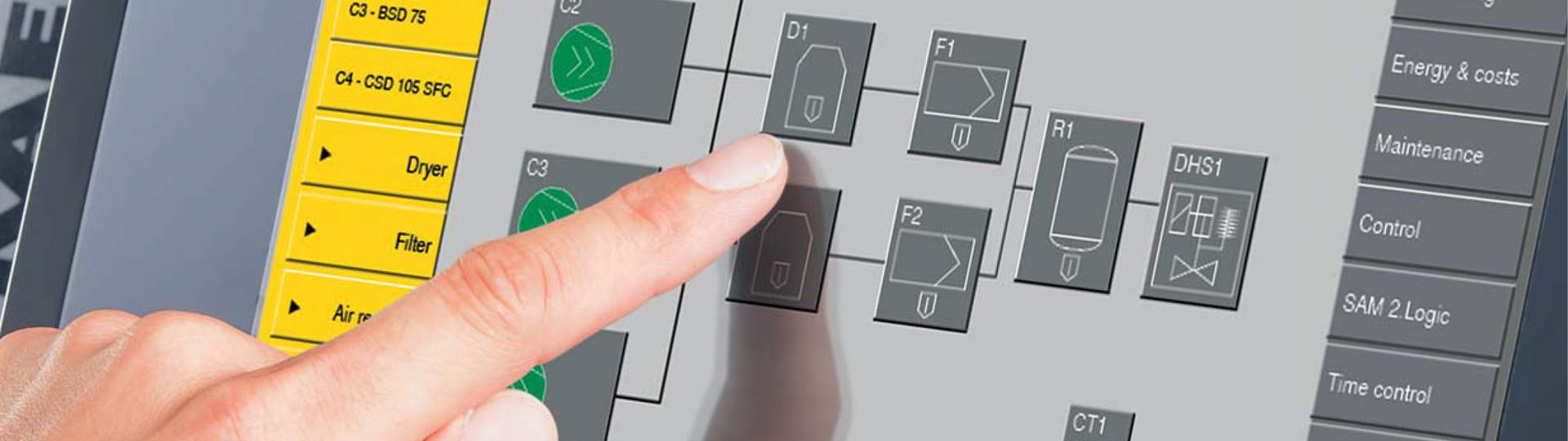

The SAM 4, the next-generation master compressed air management system, uses the adaptive 3-D advanced control to make compressed air production and treatment not only faster but also more efficient and reliable. 3-D advanced control analyses all operating data on an ongoing basis, simulates alternative actions and calculates the perfect compressor combination. The result: Unprecedented energy efficiency. Maintain an overview at all times thanks to easy operation, visualisation and analysis. With secure network technology – conveniently from any PC. Predictive maintenance by KAESER specialists prevents unplanned downtime. And if you have big plans for the future: The SAM 4 is ready-designed to accommodate potential compressed air station expansion. A simple software upgrade allows an expansion of the master controller without the need for additional investment in new hardware.

Smart:

The SAM 4 not only records switching losses but also gathers information regarding all dimensions that affect your compressed air station. Using this data, the SAM 4 then calculates the perfect parameters for optimum performance and controls all connected components accordingly.Secure:

Together with the powerful Ethernet-based KAESER SIGMA NETWORK, the SAM 4 forms a future-proof infrastructure that meets all requirements for a highly secure industrial control system.Efficient:

Continuous fine adjustment to achieve optimum energy efficiency (energy management in accordance with ISO 50001) and the option of predictive, demand-oriented maintenance keeps life cycle costs at an absolute minimum.

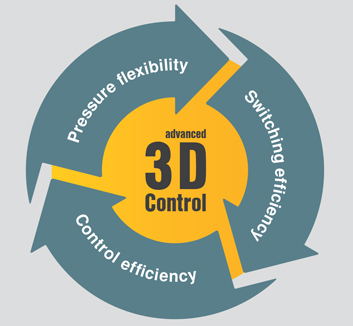

Adaptive 3-D advanced control

The innovative adaptive 3-D advanced control not only takes switching losses (start/stops) into account but also considers additional parameters that influence compressed air system energy efficiency, such as energy consumption due to control losses (idling FC losses) and pressure flexibility. The adaptive 3-D advanced control ensures optimum efficiency at all times by continuously analysing the relationship between these parameters, predictively calculating the optimum values from various possibilities, and controlling the connected compressors accordingly. The demand pressure provides the foundation for the adaptive calculation of switching events and is therefore kept to an absolute minimum. Simple software upgrade for compressed air station expansionSIGMA CONTROL 2

Fitted to all compressors as standard.

Sigma Control 2 (SC2) – The latest evolution in the KAESER on-board air compressor control system (machine controller) provides several innovations in Energy Efficiency. New Control Modes like Dynamic Control measure the operating temperature of the main drive motor continuously, enabling the SC2 to determine the best course of action for the compressor, whether it is more efficient to stop or continue running.