Rotary Screw Air Compressors

KAESER Screw Compressors & Industrial Air Compressors - Innovation meets Efficiency

Get a Free Quote Rotary screw compressors supply production processes in industry, trade and workshop applications with a reliable supply of quality compressed air. They are the preferred choice for users requiring constant pressure over prolonged periods. More and more customers throughout the world rely on HPC KAESER quality compressed air systems and benefit from optimum compressed air availability combined with low life-cycle costs. Supplied as belt drive from 2.2 kW - 22 kW & direct drive from 18.5 kW - 515 kW with oil-free dry screw model options from 30 kW - 355 kW. All compressors have an operating pressure range from 5.5 bar - 15 bar, rated at 100% Full Load Duty. Lower pressures are available on request.

Belt Drive Screw Compressors

2.2 kW – 22 kW

Direct Drive Screw Compressors

18.5 kW – 515 kW

Oil Free Screw Compressors

30 kW – 355 kW

The KAESER SIGMA PROFILE

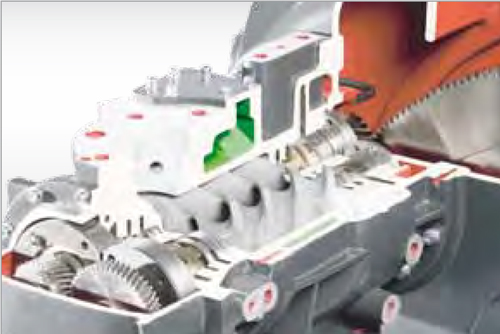

Developed by KAESER and continually enhanced ever since, the KAESER SIGMA PROFILE brings power savings of up to 15 percent compared with conventional screw airend rotor profiles. All KAESER rotary screw airends feature this energy-saving rotor profile and are designed to ensure maximum energy-efficiency. The generously-sized, precision-aligned roller bearings and close-tolerance machining guarantee long service life and outstanding reliability. Industrial rotary screw compressors supply production processes in industry, trade and workshop applications with a reliable supply of quality compressed air. They are the preferred choice for users requiring constant pressure over prolonged periods. To ensure that KAESER rotary screw compressors operate as efficiently as possible, KAESER developed its own special rotor profile. SIGMA profile rotors provide you with energy savings of up to 15% compared with conventional rotor profile designs. Furthermore, KAESER airends with SIGMA profile rotors boast an exceptionally long service life. This is in no small part due to the special roller bearings that are precision adjusted and generously sized. Combine this with in-house high-end manufacturing processes with lowest possible manufacturing tolerances and you have an exceptional product.Belt Drive Screw Compressors

Belt Drive – (SX – ASK)

The Kaeser / HPC belt drive rotary screw compressors range is between 2.2kW - 22kW. With options of Integrated Dryers, Receiver Mounted, Variable Speed Drive and Aircenter, there is a machine to suit everybody's requirements. The compressors are optimally controlled by the built-in Sigma Control 2 as standard. Fitted as standard with IE3 Premium Efficiency Siemens Electric Motors (5.5 kW and above)* and combined with the World Renowned Kaeser Sigma Profile Airend, all compressors are market leaders in efficiency and reliability. The Kaeser automatic belt tensioner device ensures constant transmission efficiency and reduced maintenance costs throughout the belts operational life. * All new 7.5 kW SM13 & 9 KW SM16 Compressors now fitted with IE4 Super Premium Efficiency Siemens Electric Motors.

Direct Drive Screw Compressors

Direct Drive - (ASD – HSD)

The HPC/Kaeser 1:1 direct drive rotary screw compressors range between 18.5kW – 515kW With options of integrated dryers, variable speed drive and built-in heat recovery. All compressors are fitted as standard with IE4 Super Premium Efficiency Electric Drive Motors which are controlled for optimum efficiency by the Sigma Control 2, providing a variety of efficient control modes to minimise costly offload running.Why 1:1 drive?

In compressed air packages featuring 1:1 direct drive the motor drives the airend directly without transmission loss via a maintenance-free coupling. 1:1 direct drive rotary screw compressors provide outstanding performance and enable significant savings. KAESER's comprehensive range of specially designed airends are manufactured and developed to meet every compressed air user’s needs.Triple savings with 1:1 drive:

No power transmission losses. Large, low speed airends provide more air for less energy. Significantly reduced maintenance costs.

Downloads

ASD Series Brochure

0.89 to 6.39 m³/min

18.5 to 30 kW BSD Series Brochure

1.12 to 8.19 m³/min

30 to 45 kW

BSD Series Brochure

1.12 to 8.19 m³/min

30 to 45 kW

CSD(X).6 Series Brochure

1.1 to 19.4 m³/min

45 to 110 kW

DSD Series Brochure

3.5 to 26.6 m³/min

75 to 132 kW

CSD(X).6 Series Brochure

1.1 to 19.4 m³/min

45 to 110 kW

DSD Series Brochure

3.5 to 26.6 m³/min

75 to 132 kW DSDX Series Brochure

4.8 to 34.25 m³/min

132 to 160 kW

DSDX Series Brochure

4.8 to 34.25 m³/min

132 to 160 kW ESD Series Brochure

6.2 to 47.2 m³/min

200 to 250 kW

ESD Series Brochure

6.2 to 47.2 m³/min

200 to 250 kW FSD Series Brochure

9.65 to 61.4 m³/min

250 to 315 kW

FSD Series Brochure

9.65 to 61.4 m³/min

250 to 315 kW HSD Series Brochure

8 to 89m³/min

360 to 515 kW

HSD Series Brochure

8 to 89m³/min

360 to 515 kW

BSD Series Brochure

1.12 to 8.19 m³/min

30 to 45 kW

BSD Series Brochure

1.12 to 8.19 m³/min

30 to 45 kW

CSD(X).6 Series Brochure

1.1 to 19.4 m³/min

45 to 110 kW

DSD Series Brochure

3.5 to 26.6 m³/min

75 to 132 kW

CSD(X).6 Series Brochure

1.1 to 19.4 m³/min

45 to 110 kW

DSD Series Brochure

3.5 to 26.6 m³/min

75 to 132 kW DSDX Series Brochure

4.8 to 34.25 m³/min

132 to 160 kW

DSDX Series Brochure

4.8 to 34.25 m³/min

132 to 160 kW ESD Series Brochure

6.2 to 47.2 m³/min

200 to 250 kW

ESD Series Brochure

6.2 to 47.2 m³/min

200 to 250 kW FSD Series Brochure

9.65 to 61.4 m³/min

250 to 315 kW

FSD Series Brochure

9.65 to 61.4 m³/min

250 to 315 kW HSD Series Brochure

8 to 89m³/min

360 to 515 kW

HSD Series Brochure

8 to 89m³/min

360 to 515 kW

Oil Free Screw Compressors

Dry Running Screw Compressors

2-Stage, Free air delivery up to 51 m³/min, Pressure 4, 6, 8 and 10 barThe new dimension in oil-free compression

Two-stage dry-running KAESER rotary screw compressors not only impress with their meticulous design, but also with their many innovative details - all of course with renowned KAESER Quality.

Long-term efficiency

Compressed air simply has to be available where and whenever it is needed. KAESER 2-stage dry-running rotary compressors are therefore built to last and to ensure many years of dependable performance. Comprising tried and tested components that have been developed as a result of KAESER‘s near century of experience in mechanical engineering, KAESER compressors deliver the durability and compressed air availability to meet even the toughest of demands.Innovation you can trust

Using all of the advantages that KAESER's advanced Research and Development Centre in Coburg has to offer, KAESER engineers created an innovative package concept designed around the 2-stage dry-running rotary screw airend. As a result, KAESER dry-running screw compressors are available, for example, with air-cooling for drive powers up to 355 kW.